Improvement of Biobased Catalyst for Biodiesel Production from Waste Cooking Oil

In order to attain net zero carbon emissions by 2050 and meet a 45% of biofuel production from waste resources target by 2030, there is the need to explore catalysts for increasing biofuel yield. This work will explore the use of environmentally benign materials for biodiesel production.

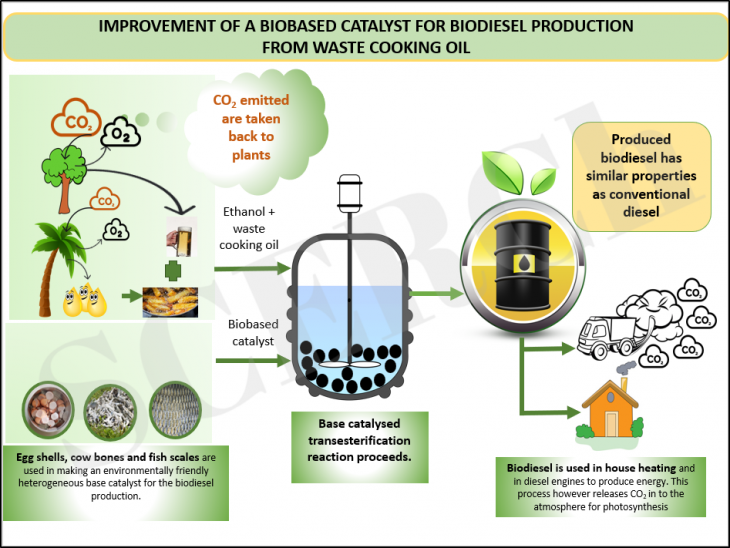

Through photosynthesis, plants use water and CO2 in the atmosphere produce oxygen and glucose which is converted to alcohol (ethanol) on fermentation. Some plants can synthesize oils. This process helps in reducing the carbon content in the atmosphere as afforestation is being encouraged for this purpose. However, the use of fossil-based fuels releases enormous amounts of CO2 into the atmosphere. This release effect cannot be curbed by plant photosynthesis only. Bio-based fuels have relatively lower carbon content and hence release relatively minimal amounts of CO2 during energy production. Recycling of CO2 produced from biofuels (biodiesel) into plants via photosynthesis, to produce oxygen as a by-product, yields a net zero carbon emission into the atmosphere. Waste cooking oil (WCO) from restaurants and ethanol will be used as the main raw materials for the biodiesel production via transesterification reaction.

Heterogeneous catalysts have attracted great attention in recent times for use in biodiesel production. The need for the development of heterogeneous catalysts has risen because homogeneous catalysts used for biodiesel production pose some drawbacks, such as wastewater generation and loss of biodiesel as a result of washing. Various environmentally benign catalysts are being developed to increase biodiesel yields and quality. Cheap yet efficient catalysts, including fish scales, cow bones, and eggshells, are being investigated in this research due to their high CaO content, which has higher basicity, is non-corrosive, easier to handle than homogenous catalysts, and is safe to the ecosystem which makes it an interesting choice for a catalyst. The main purpose of this research work is to modify fish scales, cow bones, and eggshells as environmentally benign catalysts to have a large surface area and high basicity to enhance the production of biodiesel from waste cooking oil feedstock. The catalyst production procedure will also be varied in terms of catalyst mix ratio, catalyst mix procedure and catalyst impregnation species. The best performing catalyst will be characterized by BET, XRD, XRF, SEM, TGA and CO2-TPD techniques. The transesterification reaction parameters will be specified for the best performing catalyst blend [catalyst dose, reaction temperature, stirring rate and reaction time, WCO to ethanol ratio] to determine the optimum conditions. GC-MS will be used to quantify the purity (FAME composition) of the produced biodiesel.